Improvement has been noticed significantly in the 3D printing industry. Also, every day a new printing technology is being developed. To further improve this new printing technology, several new ideas like vacuum casting has been introduced. This service is being offered by several industries to provide benefits to people all over the world.

This post will discuss what vacuum casting is and its benefits. Also mentioned in this article is how the process goes.

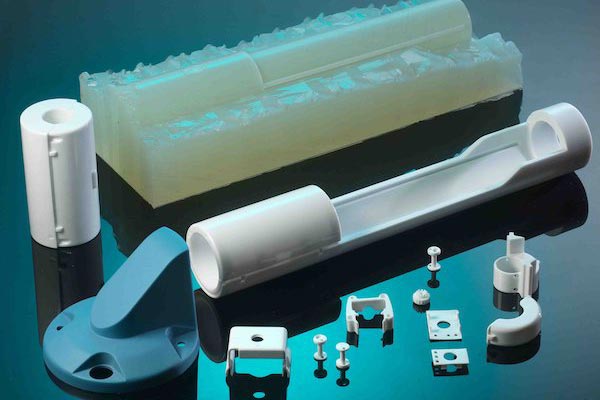

Vacuum casting products

The Vacuum Casting Process

The process was developed to provide an innovative method in producing prototypes of different industrial parts. Casting makes use of a master model of premium quality needed to create more prototypes.

Stereolithography is the process used in producing the model. The master model must be made of premium quality material and without flaws to ensure the generated prototype is of high-quality.

It starts by placing the mold in a cast made of silicon rubber that is subjected to a very high temperature. The next step is to create a master mold that is empty from the center. The liquid material is then added into the pattern to copy the shape of the master model under a vacuum chamber. Polyurethane resin-like polyethylene and polycarbonate is a popular filling material for this type of prototyping.

Metallic powder is then added into the filled resin to achieve the required properties. Cover the mold inside the chamber to make sure there are no air bubbles developed. Place the mold in the oven. After the completion of the molding process, the pattern is taken out for the production of more parts.

Paint the prototype based on the required color. The finished product is then distributed in the market so it can reach your target consumers.

After knowing the process, let us discuss the benefits of vacuum casting so you can decide if it can help your business or not.

The Vacuum Casting Benefits

Quality

You have the liberty to choose the best material for your product. Base your selection according to your desired hardness of its parts. The most reliable liquid material used by most manufacturers is the polyurethane resins. It can provide the hardness and flexibility that you need for your product. Painting the product is easy, as the material used is quite reliable. As a result, an impressive product that your consumers will surely love.

High Precision

The prototype produces parts similar to the original model. Vacuum casting can produce even complex parts with typical geometries that can be created easily. Likewise, the final product is of high-precision.

Meet Deadlines and Prices

The process does not require you to spend a lot. As a result, you can produce more prototypes. It is more helpful and valuable as compared to other printing technology. You can produce around 30 to 50 prototype parts within 15 days, which is more useful during the urgent needs.

Vacuum casting is a careful process that you can use if you want to test your product in the market. You can finalize the production of your products once you get a response from the consumers. Because of this, you are assured that your product is of top quality, and the consumers will love it.