Plastic Injection Molding

From conventional injection molding to lastest injection molding technicals.

In-Mold Decoration

- Ultra-Durable

- All-in-One Process

- Cost-Efficient

- From 1 to 1,000 parts

Liquid Silicone Rubber Molding

- Heat & Chemical Resistant

- Flexible & Durable

- Precision & Cleanliness

- From 1 to 10,000 parts

Insert Molding

- Stronger Parts

- Simplified Assembly

- Cost-Efficient

- From 1 to 10,000 parts

Plastic Injection Molding Introduction

Plastic injection molding is a manufacturing process used to produce large volumes of identical plastic parts with high precision. It involves injecting molten plastic into a mold, where it cools and solidifies into the desired shape.

How It Works:

- Clamping – A two-part mold is securely closed under high pressure.

- Injection – Molten plastic is heated and forced into the mold cavity under high pressure.

- Cooling – The plastic cools and hardens inside the mold.

- Ejection – The mold opens, and the finished part is ejected.

Key Components:

- Injection Molding Machine (Clamping unit & Injection unit)

- Mold (Custom-designed steel or aluminum tool)

- Raw Material (Thermoplastics like ABS, Polypropylene, Nylon, etc.)

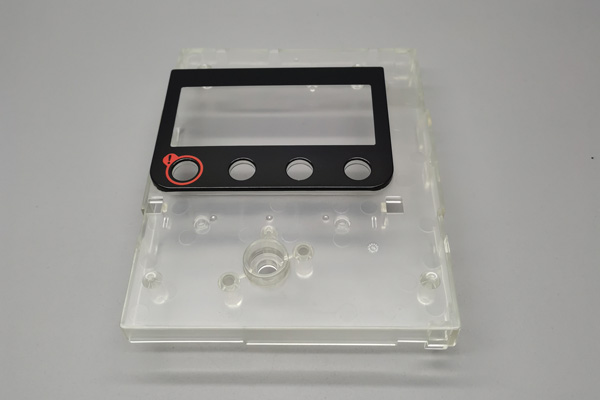

In-Mold Decoration (IMD) – Introduction

In-Mold Decoration Parts

Made by Longim

In-Mold Decoration (IMD) is an advanced manufacturing process that integrates decoration directly into plastic parts during injection molding. A pre-printed film or foil is placed into the mold before injecting molten plastic, resulting in a seamless, durable, and high-quality decorated surface.

Key Features of IMD:

- Single-Step Process: Combines molding and decoration in one operation.

- High Durability: Graphics are embedded within the part, resisting scratches, UV fading, and chemicals.

- Design Flexibility: Supports full-color prints, textures, metallic finishes, and even 3D effects.

Common Applications:

- Automotive: Dashboard panels, control buttons, logos

- Electronics: Smartphone/tablet casings, touchscreen bezels

- Consumer Goods: Appliance panels, cosmetic packaging

- Medical Devices: Durable, sterilizable labels

Advantages Over Traditional Methods (Painting/Pad Printing):

✔ No post-processing needed (reduces cost/time)

✔ Superior scratch/weather resistance

✔ Lightweight & seamless integration

IMD is ideal for high-volume production of parts requiring premium aesthetics and long-lasting durability.

Incredibe Extremely

Easy to Collaborate with Globally, and Delivers Your Parts on Time.

A reliable partner that makes collaboration effortless and delivers precision parts on time, every time.

Case Studies

Parts & Products

While these examples highlight our plastic injection molding capabilities, they represent just a fraction of our expertise. With an extensive portfolio spanning consumer electronics, automotive, and medical applications, we’ve successfully delivered complex, precision-crafted components that consistently meet the most demanding quality standards and customized specifications. Our advanced tooling technologies and cross-industry experience position us to bring the same level of excellence to your project – let’s discuss how we can exceed your expectations.