Surface Finishing

Perfection in Every Layer – Flawless Finishes, Every Time.

Elevate Your Product with Expert Surface Finishing

At Longim, we specialize in high-quality surface finishing solutions designed to enhance the durability, functionality, and aesthetics of your products. Whether you need a smooth polish, a protective coating, or a decorative finish, our advanced techniques ensure precision and consistency for metals, plastics, and composites.

Why Surface Finishing Matters

Surface finishing is a critical step in manufacturing that transforms raw materials into high-performance, market-ready products. Here’s why it’s indispensable:

- Enhanced Durability – Protects against wear, corrosion, and environmental damage, extending product lifespan.

- Superior Aesthetics – Delivers smooth, polished, or textured finishes that improve visual appeal and brand perception.

- Improved Functionality – Reduces friction, enhances conductivity, or adds grip for better performance.

- Regulatory Compliance – Meets industry standards (e.g., FDA, automotive, aerospace) for safety and quality.

- Increased Value – A flawless finish elevates perceived quality, giving you a competitive edge.

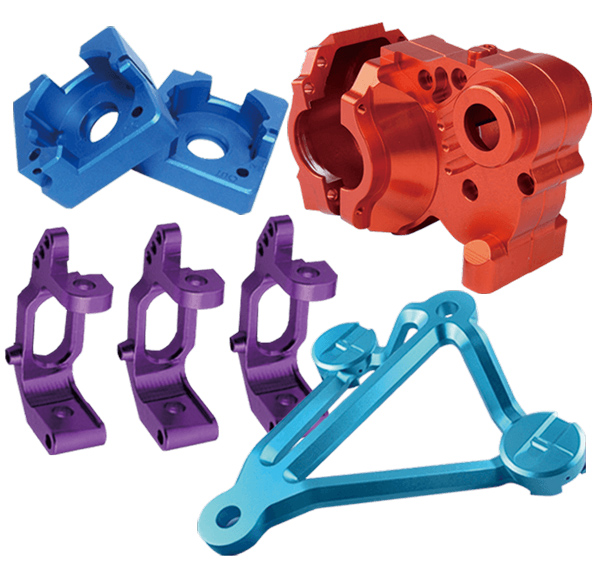

Anodizing

Anodizing is an electrochemical process that converts a metal surface into an anodized oxide finish. It is most commonly applied to aluminum alloys, but can also be used on other metals such as titanium and magnesium. The process enhances properties such as corrosion resistance, wear resistance, and the ability to hold dyes for coloring, making anodized surfaces both functional and aesthetically pleasing.

Vapor Polishing

Vapor polishing, or solvent vapor polishing, is a surface finishing technique designed to enhance the appearance and smoothness of plastic parts, particularly those made through 3D printing or injection molding. It involves exposing plastic surfaces to solvent vapor, which softens and smoothes the surface without harming the material underneath.

Several plastics respond well to vapor polishing, including polycarbonate, acrylic (PMMA), acrylonitrile butadiene styrene (ABS), polysulfone, and polyetherimide (PEI). This process enhances their surface sharpness and overall appearance.

Pad Printing

Pad printing is a printing process that allows images to be transferred onto a variety of substrates, making it particularly popular for printing on 3D or irregularly shaped objects.

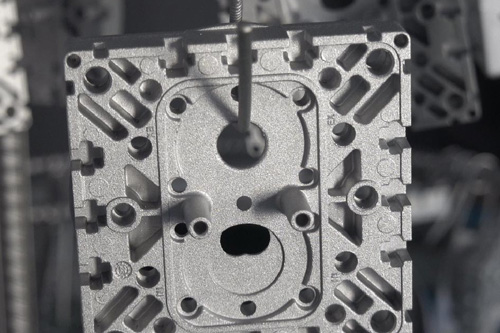

Sandblasting

Powder coating is a finishing process in which a dry powder is applied to a surface, which is then cured under heat to form a durable, protective coating.

Powder Coating

Sandblasting, also known as abrasive blasting, is a surface preparation technique used to clean, smooth, or etch surfaces by forcibly pushing a stream of abrasive material, often sand, against them.

There are several types of sandblasting, including wet sandblasting, vapor blasting, bead blasting, wheel blasting, and vacuum blasting, each designed for specific applications and surfaces.