CNC Machining Services

Turning and Milling the arts.

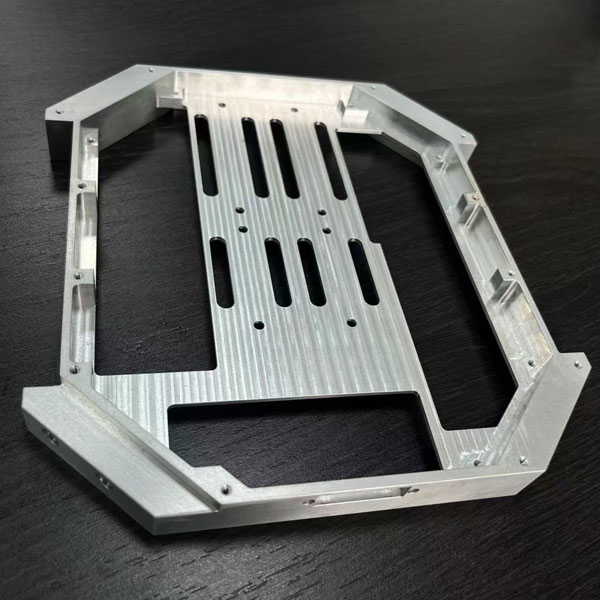

CNC Milling

- High Precision Parts

- Complex Shapes Possible

- Fast Repeatable Production

- From 1 to 1,000 parts

CNC Turning

- Precision Cylindrical Parts

- Fast Production Rates

- Low Material Waste

- From 1 to 1,000 parts

Milling and Turning

- Versatile Part Geometries

- High Precision Finishes

- Efficient Mass Production

- From 1 to 1,000,000 parts

Precision CNC Machining

CNC (Computer Numeric Control) machining services harness advanced technology to operate fast, repeatable, and programmable machines, significantly enhancing the efficiency of part production. These CNC machines, governed by precision controllers, streamline the manufacturing process, allowing for faster turnaround times.

One of the key advantages of CNC machining is its ability to create intricate geometries that would be challenging to achieve with traditional hand-crafted methods. By replacing regular tools and skilled labor with high-precision machinery, manufacturers can dramatically reduce costs and minimize production time.

Stainless Steel Parts

April 23, Milled @ Longim

From design to prototype, inspected and shipped out, in 3 days. P20

Machining Process

Design: Begin with a Computer-Aided Design (CAD) model that defines the part’s specifications.

Tool Path Creation: Convert the CAD model into a Computer-Aided Manufacturing (CAM) file to generate a tool path for the CNC machine.

Programming: Generate CNC code (G-code or M-code) from the CAM file and upload it to the CNC machine.

Machining Operation: Set up the CNC machine with the necessary tools. The machine executes the programmed tasks, cutting and shaping materials as needed, with automatic tool changes if required.

Finishing: Complete any additional surface finishing processes, such as sanding, polishing, or coating.

On Demand

Global CNC Machining Solutions

Advanced 5-axis, 4-axis, 3-axis cnc machines with experienced engineers will fully understand and meet your requirements.

Case Studies

Parts & Products

Beyond these CNC machining examples, we possess an extensive portfolio showcasing our advanced capabilities, precision engineering, and diverse industry expertise. Our proven track record includes complex projects across aerospace, automotive, and medical sectors—each meeting stringent quality standards and customized requirements. Let us demonstrate how our experience can deliver excellence for your next project.